ТОР 5 статей:

Методические подходы к анализу финансового состояния предприятия

Проблема периодизации русской литературы ХХ века. Краткая характеристика второй половины ХХ века

Характеристика шлифовальных кругов и ее маркировка

Служебные части речи. Предлог. Союз. Частицы

КАТЕГОРИИ:

- Археология

- Архитектура

- Астрономия

- Аудит

- Биология

- Ботаника

- Бухгалтерский учёт

- Войное дело

- Генетика

- География

- Геология

- Дизайн

- Искусство

- История

- Кино

- Кулинария

- Культура

- Литература

- Математика

- Медицина

- Металлургия

- Мифология

- Музыка

- Психология

- Религия

- Спорт

- Строительство

- Техника

- Транспорт

- Туризм

- Усадьба

- Физика

- Фотография

- Химия

- Экология

- Электричество

- Электроника

- Энергетика

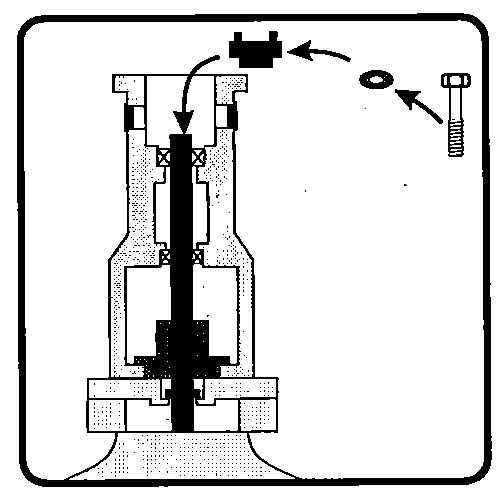

Dismantling the Agitator Lantern

● Push the agitator lantern (3005) onto the shaft (3700/6000)

● Remove the lifting gear ● Connect the agitator lantern (3005) to the mounting flange (4500) — tighten the screws crosswise with half the final torque value, then with crosswise with the full torque value (final torque value → table chapter 4.4)

|

● Loosen the hexagon screws (5774) on the clamping segments (5772) and remove the clamping segments

● Push down the seal housing and evenly tighten it to the mounting flange (tightening torques → table chapter 4.4)

| ● Put the coupling part B (3010) onto the shaft ● Mount the bolting (3065/3070)) |

By tightening the bolt (3065) the shaft and the impeller(s) get lifted from the suspension device (5780) again — hence an increased resistance during tightening is normal

● Tighten the hexagon bolt (3065) with the tightening torque acc. to the table (→ chapter 4.4)