ТОР 5 статей:

Методические подходы к анализу финансового состояния предприятия

Проблема периодизации русской литературы ХХ века. Краткая характеристика второй половины ХХ века

Характеристика шлифовальных кругов и ее маркировка

Служебные части речи. Предлог. Союз. Частицы

КАТЕГОРИИ:

- Археология

- Архитектура

- Астрономия

- Аудит

- Биология

- Ботаника

- Бухгалтерский учёт

- Войное дело

- Генетика

- География

- Геология

- Дизайн

- Искусство

- История

- Кино

- Кулинария

- Культура

- Литература

- Математика

- Медицина

- Металлургия

- Мифология

- Музыка

- Психология

- Религия

- Спорт

- Строительство

- Техника

- Транспорт

- Туризм

- Усадьба

- Физика

- Фотография

- Химия

- Экология

- Электричество

- Электроника

- Энергетика

Choice of constructive materials

Packed column absorbers are downloaded from the nozzle bodies of various shape (ring wooden lattice particulate material, etc.). Gas-liquid contact occurs mainly on the wetted surface of the nozzle at which the scrubbing liquid flows. The surface of the nozzle unit to unit volume can be quite high and therefore a relatively small volume can create significant mass transfer surface. However, in some cases, surface active surface. Fluid flow in the nozzle is essentially the character of the film, resulting in packed absorbers can be regarded as a kind of film. At the same time, between the packings and film absorbers, absorbers including a nozzle sheet, there are differences. The film absorbers liquid film flow occurs over the entire height of the machine, whereas in the checkerwork - a packing element height. When the liquid overflow from one packing element to another liquid film is destroyed and a new film is formed on the underlying element. Some of the liquid thus falls as droplets through a nozzle located below the layers. Under certain conditions, the liquid film flow in packed absorbers broken, and the contact between gas and liquid is carried in the bubbling regime.

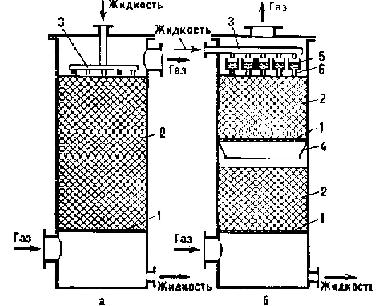

The packed absorber (. Figure 1) consists of a column, in which the supporting grate 1 is placed; this lattice is laid a layer of packing 2. scrubbing liquid is fed to the nozzle by means of the dispenser 3. In the illustrated in Fig. 5 and nozzle absorber laid continuous layer over the entire height. Sometimes the nozzle is laid several layers, each separate setting a lattice supporting layer (Fig. 1 b). In some cases, lay-nozzle between the individual layers of the device 4 is set to redistribute the liquid.

Fig.1 packed absorbers:

and - with a continuous nozzle loading; b - with primary store attachments;

1 - supporting lattice; 2 - head; 3 - liquid distribution device;

4 - redistributor; 5 - gutter; 6 pipe.

The movement of gas and liquid in the packed countercurrent absorbers typically performed as illustrated in Fig. 5. Co current regeneration (downlink) is used rarely. Recently, however, a lot of attention paid to the creation of direct-flow packed absorbers working with large gas rates (up to 10 m / s). At such speeds, which in the case of counterblow unattainable because of the occurrence of flooding, it intensifies the process and reduced size apparatus; concurrent with the flow resistance is considerably lower than in counterblow. The use of such absorbers is expedient in cases where the direction of motion of the phases does not affect significantly the driving force.

Lack of packed absorbers - the difficulty of heat dissipation using outrigger refrigerators. The proposed design absorbers with internal heat removal by means of a nozzle placed in the cooling members do not receive.

The packed column liquid flows through the nozzle element is mainly in the form of a thin film, so the phase contact surface is substantially wetted surface nozzles, and packed devices may be considered as a kind of film. However, in the past the liquid film flow occurs over the entire height of the machine, and packed absorbers - only packing element height. When the liquid overflow from one packing element to another liquid film is destroyed and a new film is formed on the underlying element. In this part of the fluid passes through the layers located below the nozzle in the form of jets, droplets and sprays. Part of the nozzle surface is wetted with a fixed (stagnant) liquid.

The basic characteristics of a nozzle and its specific surface area (m2 / m3) and the free volume of e (m3 / m3). The amount of free volume for non-porous nozzle is usually determined by water filling nozzle. The ratio of water volume to the volume occupied by the nozzle, the magnitude e gives. The equivalent diameter of the nozzle is according to the formula

Hydrodynamic modes. Packed absorbers can operate in different hydrodynamic regimes.

The first mode - the film - there is at low densities, irrigation and low gas speeds. The amount of liquid holdup in the nozzle at the same time is practically independent of the gas velocity.

The second mode - hang mode. When countercurrent phases due to an increase of the liquid phase to the gas contact surface friction force occurs braking fluid gas stream. As a result, the fluid flow rate decreases and the thickness of the film and the amount of fluid retained in the nozzle increases. The hang time with an increase in the gas velocity increases the wetted surface of the nozzle and respectively - the intensity of the mass transfer process. In quiet mode, hang over the film is broken: there are swirls, splashes, ie create conditions for the transition to the bubbling. All this contributes to increase the mass transfer rate.

Не нашли, что искали? Воспользуйтесь поиском: