ТОР 5 статей:

Методические подходы к анализу финансового состояния предприятия

Проблема периодизации русской литературы ХХ века. Краткая характеристика второй половины ХХ века

Характеристика шлифовальных кругов и ее маркировка

Служебные части речи. Предлог. Союз. Частицы

КАТЕГОРИИ:

- Археология

- Архитектура

- Астрономия

- Аудит

- Биология

- Ботаника

- Бухгалтерский учёт

- Войное дело

- Генетика

- География

- Геология

- Дизайн

- Искусство

- История

- Кино

- Кулинария

- Культура

- Литература

- Математика

- Медицина

- Металлургия

- Мифология

- Музыка

- Психология

- Религия

- Спорт

- Строительство

- Техника

- Транспорт

- Туризм

- Усадьба

- Физика

- Фотография

- Химия

- Экология

- Электричество

- Электроника

- Энергетика

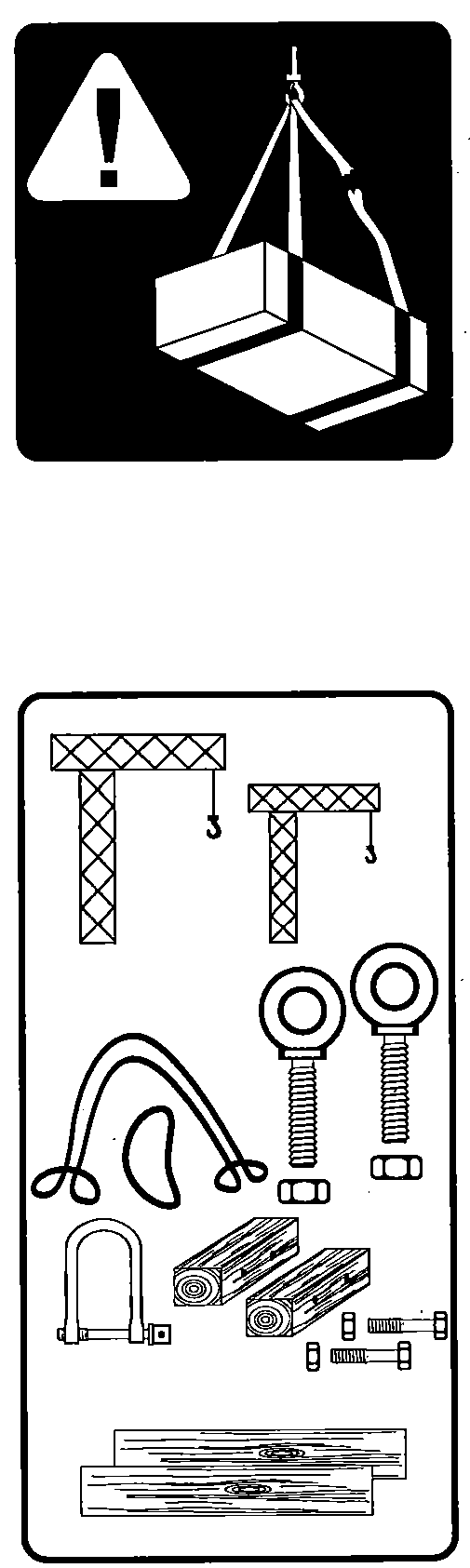

Lifting the Agitator Lantern with the Drive already removed

St Alternative

● Attach min. 2, better 4 eye-bolts to the upper flange of the agitator lantern

● Attach the lifting gear to the eye-bolts and to a hook with slip-off protection

Nd Alternative

● Create loops on both ends of a long rope/belt sling from non-metallic material and attach them underneath the upper flange of the agitator lantern

| ● Tighten the loops and put the sling into a hook with slip-off protection Instead of one long sling two identical short slings can be used |

-beams), with holes and fixing screws

- other wooden beams to support the erected agitator

- generals tools

-beams), with holes and fixing screws

- other wooden beams to support the erected agitator

- generals tools