ТОР 5 статей:

Методические подходы к анализу финансового состояния предприятия

Проблема периодизации русской литературы ХХ века. Краткая характеристика второй половины ХХ века

Характеристика шлифовальных кругов и ее маркировка

Служебные части речи. Предлог. Союз. Частицы

КАТЕГОРИИ:

- Археология

- Архитектура

- Астрономия

- Аудит

- Биология

- Ботаника

- Бухгалтерский учёт

- Войное дело

- Генетика

- География

- Геология

- Дизайн

- Искусство

- История

- Кино

- Кулинария

- Культура

- Литература

- Математика

- Медицина

- Металлургия

- Мифология

- Музыка

- Психология

- Религия

- Спорт

- Строительство

- Техника

- Транспорт

- Туризм

- Усадьба

- Физика

- Фотография

- Химия

- Экология

- Электричество

- Электроника

- Энергетика

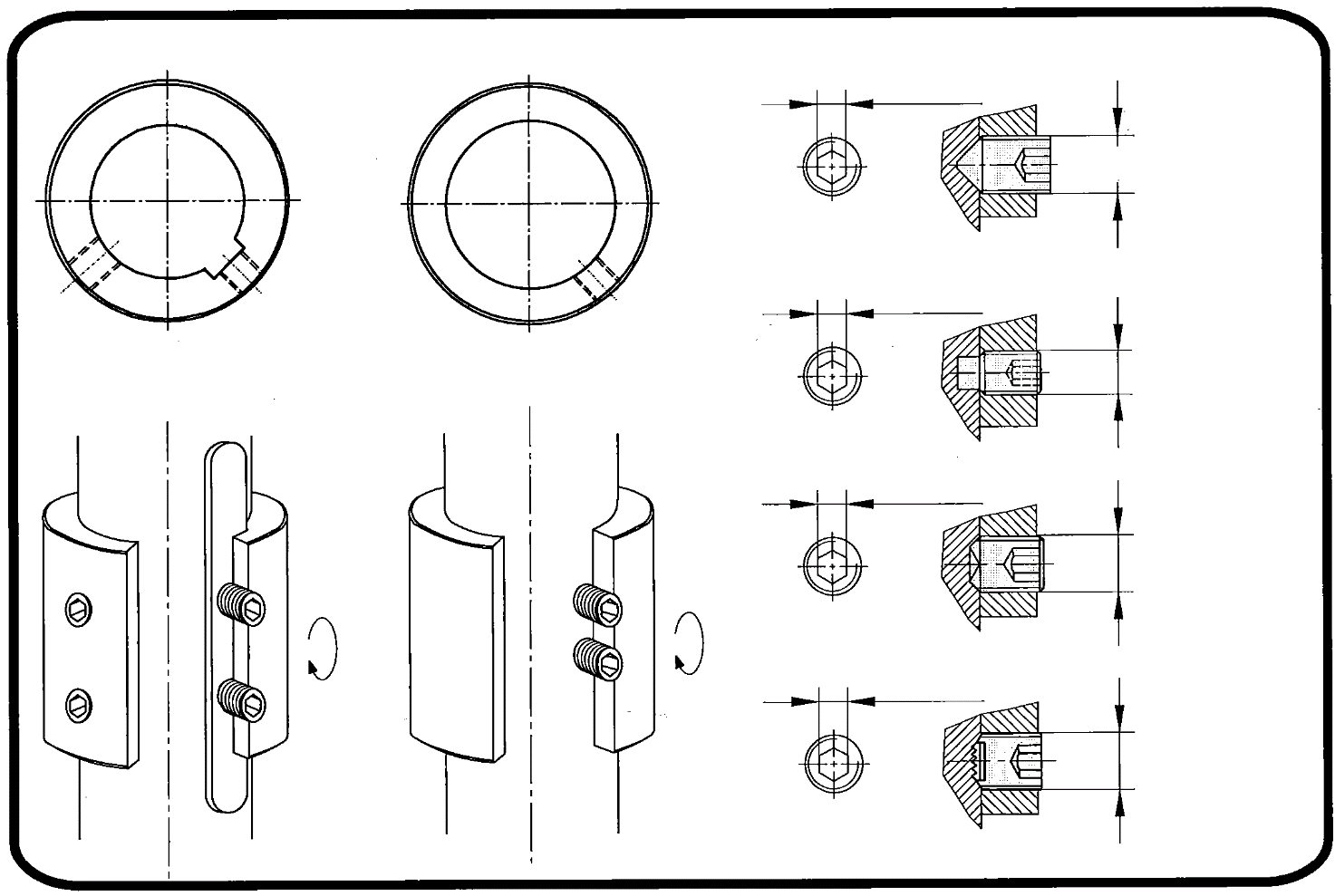

Junction Agitator Shaft - Impeller Hub

(Hub with Set Screw DIN 913, 914, 915, 916 or EKATO-Set Screws)

| EKATO |

| DIN 916 |

| DIN 915 |

| DIN 913, DIN 914 |

| G |

| G |

| G |

| G |

| SW |

| SW |

| SW |

| SW |

NOTE: After tightening the set screws or EKATO-set screws must be locked with 2 centre punch strokes ● See the parts list (→ chapter 8) for applicable parts ● Bring the impeller(s) into the vessel

● For positioning follow the dimensional sheet (→ chapter” or the general assembly drawing (when ordered, → chapter 1 or 8) ● Remove corrosion protection ● Check shaft seat, possibly key way and key, hub and attachment parts for damage With key and key way: ♦ Make sure the parallel key(s) is/аге in position (and fastened with screws if provided) | With set screws: ♦ Make sure there are spot facings for the set screw(s) on the shaft or the parallel key resp. yet ● Slip the hub onto the shaft ● Caution! ● When mounting the stirrer, take note of the installation guidelines on the stirrer. ● The side marked on the stirrer blade should be mounted pointing towards the drive. When using thread locking agents: ♦ Apply thread locking agent on the thread(s) With set screws DIN913/914/915/916: ♦ Position the hub such that the spot facings/drilling on the shaft or the parallel key line up with the set screw positions ● Insert the set screw(s》or EKATO-set screw(s) ● Tighten the set screw(s) or EKATO-set screw(s) (evenly, avoid bracing) and lock each set screw or EKATO-set screw with 2 centre punch strokes |

| Tightening torques for set screws/EKATO-set screw(s): M10 16 Nm M12 30 Nm M16 68 Nm M24 230 Nm |

Не нашли, что искали? Воспользуйтесь поиском: