ТОР 5 статей:

Методические подходы к анализу финансового состояния предприятия

Проблема периодизации русской литературы ХХ века. Краткая характеристика второй половины ХХ века

Характеристика шлифовальных кругов и ее маркировка

Служебные части речи. Предлог. Союз. Частицы

КАТЕГОРИИ:

- Археология

- Архитектура

- Астрономия

- Аудит

- Биология

- Ботаника

- Бухгалтерский учёт

- Войное дело

- Генетика

- География

- Геология

- Дизайн

- Искусство

- История

- Кино

- Кулинария

- Культура

- Литература

- Математика

- Медицина

- Металлургия

- Мифология

- Музыка

- Психология

- Религия

- Спорт

- Строительство

- Техника

- Транспорт

- Туризм

- Усадьба

- Физика

- Фотография

- Химия

- Экология

- Электричество

- Электроника

- Энергетика

Cooling down the Vessel

| CAUTION |

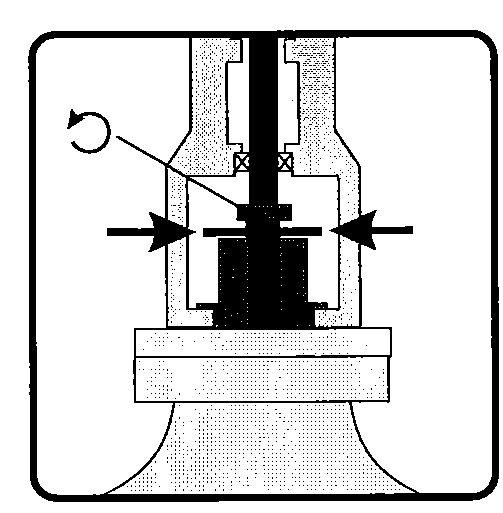

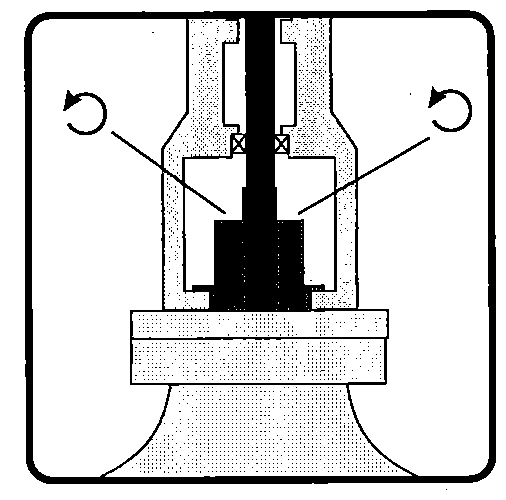

| High temperature processes also heat up the shaft in the agitator drive High-temperature processes result in heating of the shaft as far as the upper section of the agitator There is a risk of damage to the 0 rings if the buffer fluid is drained from the sliding ring seals too early or sliding ring seals are pulled onto hot shafts There is a risk of corrosion of bearings and bushing guides if attempts are made to pull sliding ring seals away from hot shafts or pull them onto hot shafts Before beginning work, let the container cool down so that the shaft temperature directly above the seal is at most 20o C above ambient temperature |

Safety Rules

| WARNING

|

| Before beginning work on the agitator check that no explosive atmosphere exists. |

| WARNING |

| The shut-off device seals the vessel when the seal is removed However the overpressure inside the vessel must be reduced to an absolute minimum before proceeding further |

| WARNING |

| The bottom of the mechanical seal and the top of the shut-off device can be contaminated with product 一 if necessary provide protective equipment and cleaning measures The dead space between the mechanical seal and the shut-off device is under vessel pressure 一 instant discharge is possible upon loosening of the mechanical seal | |

| CAUTION |

| Do not carry out work inside the vessel while the shaft is suspended | |

| CAUTION |

| The relevant laws, accident prevention regulations and recognized technical regulations for safe and specialized work with this agitator should be observed This includes using protective equipment such as helmets, shoes, protective goggles and gloves Special safety measures should be taken when a container in which a poisonous or corrosive product has been processed needs to be entered(protective clothing, breathing apparatus). |

| ● Switch-off the agitator ● Acc. to the local regulations either ♦lock the main switch or ♦pull the pertinent slide-in module at the control centre |

|

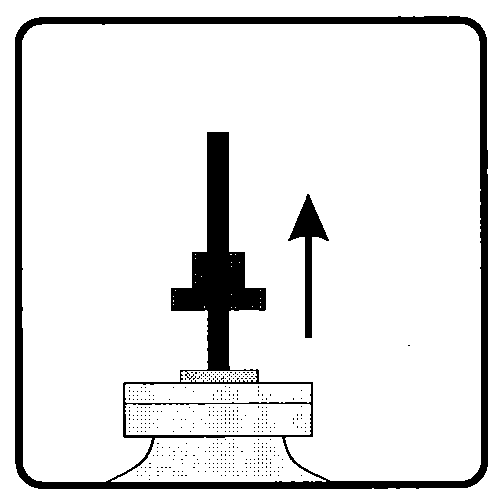

without force!) down until it rests on the: suspension device (5780)

without force!) down until it rests on the: suspension device (5780)